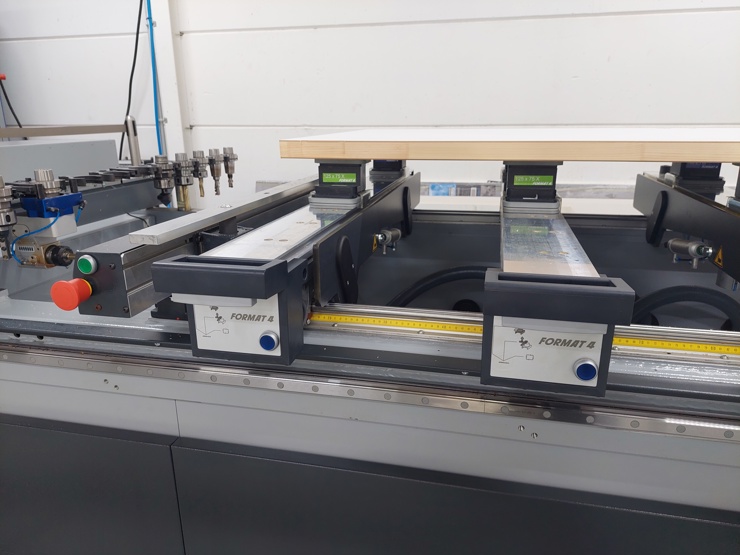

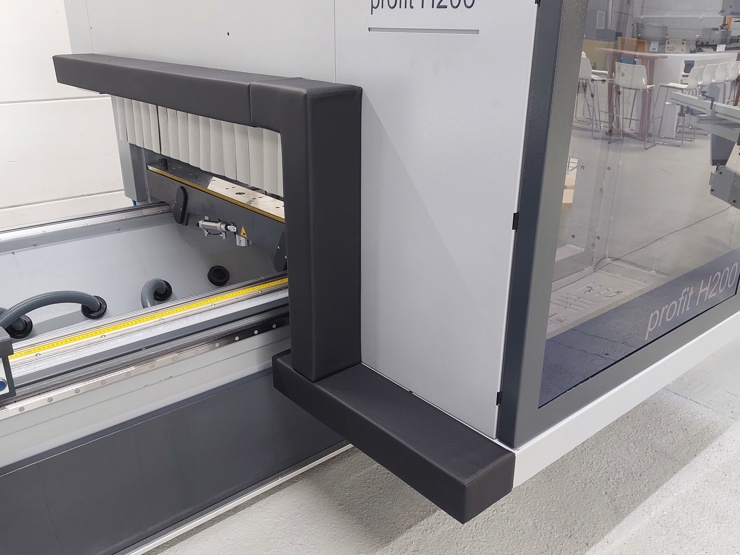

CNC Format4 H200R 13.33

M002280/M002280%20H200%20image%20overview.jpg?width=928&height=440&bgcolor=fff)

Technical Data

3x400V/50Hz CE

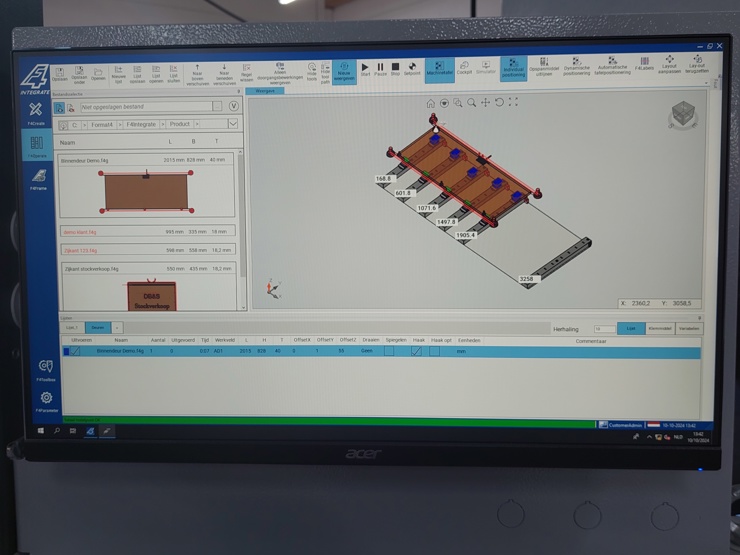

- Machining field X = 3300 mm , Y = 1280 mm, Z = 125 mm

- Automatic central lubrication

- Hand terminal for control of feed rate

- Connectivity package "light

- 1 vacuum connection for template milling operations on the left side of the machine (Ø 12 mm)

- Torque support for pump-motor unit intake- Positioning display of workpiece supports and vacuum pistons

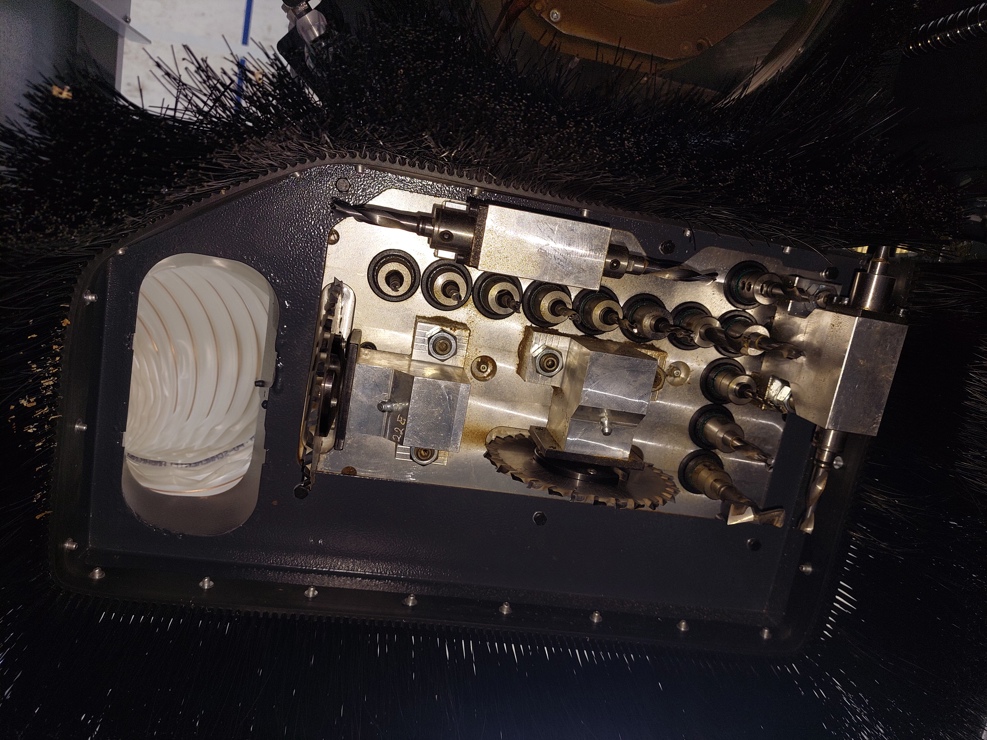

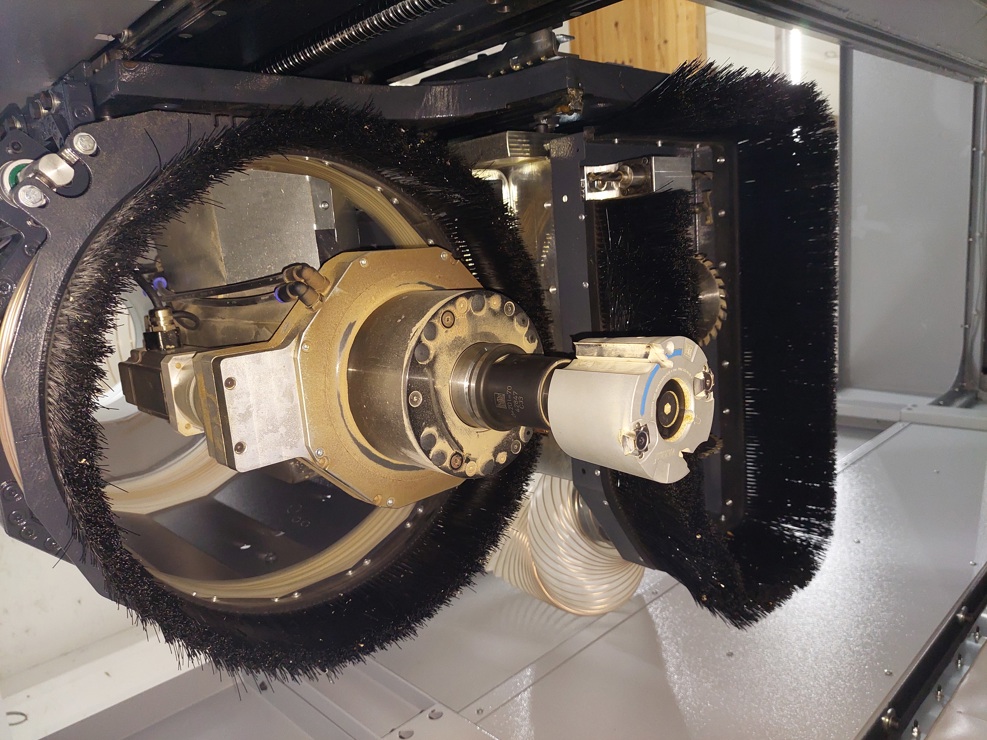

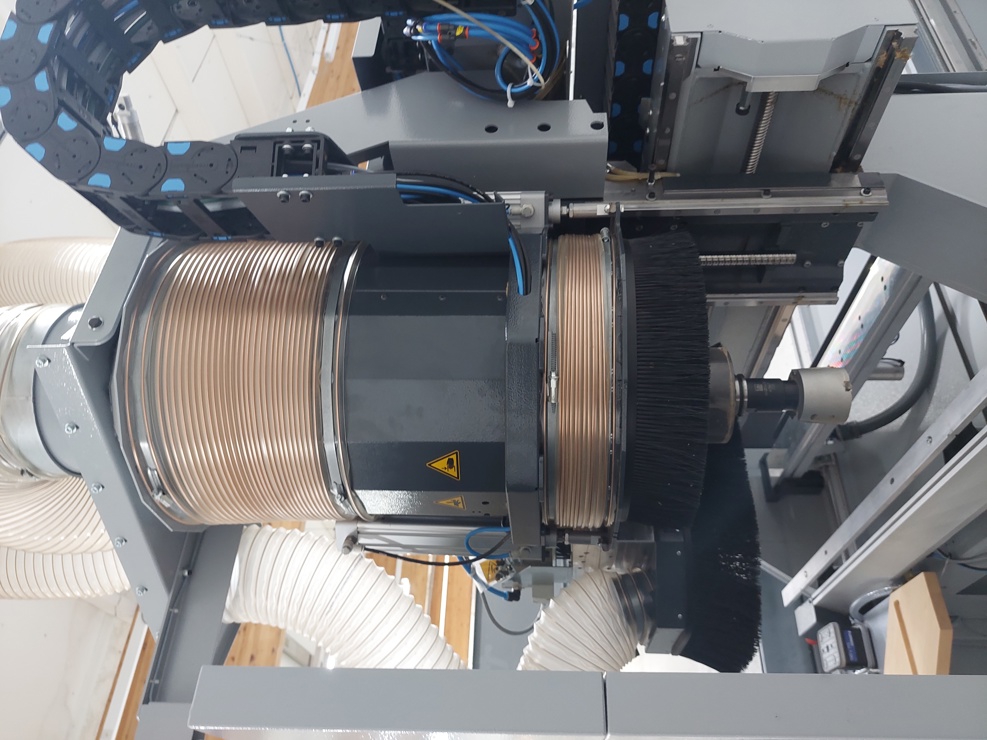

- Spindle 12 KW (S6) HSK F63; 24000t/min., ceramic bearings with pneumatically height-adjustable hood with 2 positions-Drill head DH 16 4H 2S

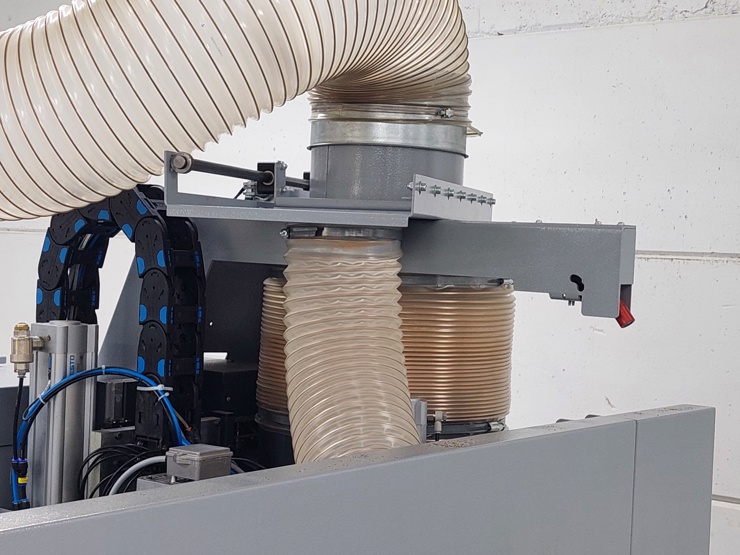

- Controlled central extraction connection

- Vacuum system 90 m³/h

- 4 vacuum suction cup 140x115x100m and 4 vacuum suction cup 125x75x100mm

- 12-fold linear tool changer on the left side of the machine frame incl. pickup space for units

- Fixed operating terminal on the left side of the machine- Protective grating on the left side of the machine

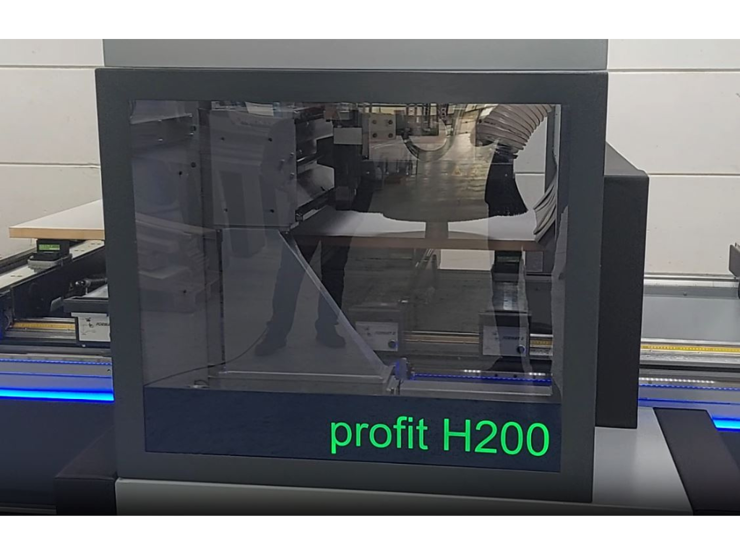

- Machine with full cover with integrated opening flap at the front of the machine

- F4Integrate" CNC software

- "F4 Design" construction software

- USV, uninterruptible power supply for PC

- Closed cable wagon in X and Y direction

- C-axis 0-360°

- 2 straight side feces (Y- direction)

- 6 consoles instead of 4

- Safety system with bumpers

- Moveable control panel

- Visual status display of the machine

- Blue LED light strip along the length of the machine

- Comfort foot switch

Similar used machnies

/Foto%20nieuwsbrief.jpg?width=376)

CNC Holztech Industrial Evo

M000799

/Evolution%203.jpg?width=376)

CNC Holztech Industrial Evolution C

M001387

Similar new machnes

/Vega%20Ultra.png?width=376)

VEGA ULTRA 1300

Pod and rail CNC working center

- Gantry design

- Top stability due to extremely heavy construction

- Maximum productivity by intuitive NC-hops user-interface

- Available in X-axis machining lengths 2500 / 3200 / 4500 / 6000 mm

- All working field stop cylinders with sensors for maximum safety

- Equipped as standard with central lubrication, automatic tool length measuring system & tool changer with crash-control sensor system

- Ultimate safety with safety systems suitable for every available space in every workshop

/Vega%20Ultra.png?width=376)

VEGA ULTRA 1600

Pod and rail CNC working center

- Gantry design

- Top stability due to extremely heavy construction

- Maximum productivity by intuitive NC-hops user-interface

- Available in X-axis machining lengths 2500 / 3200 / 4500 / 6000 mm

- All working field stop cylinders with sensors for maximum safety

- Equipped as standard with central lubrication, automatic tool length measuring system & tool changer with crash-control sensor system

- Ultimate safety with safety systems suitable for every available space in every workshop

/Vega%20Pro.png?width=376)

VEGA PRO

Pod and rail CNC working center

- Gooseneck-type machine (open at the front)

- Top stability due to extremely heavy construction

- Maximum productivity by intuitive NC-hops user-interface

- Available in X-axis machining lengths 2500 / 3200 / 4500 / 6000 mm

- Equipped as standard with automatic central lubrication, automatic tool length measuring system & rotary tool changer with 8-position servo-controlled with crash-control sensor system

- Ultimate safety with safety systems suitable for every available space in every workshop

.png?width=740)

/M002280%20H200%20image%20overview.jpg?width=740)