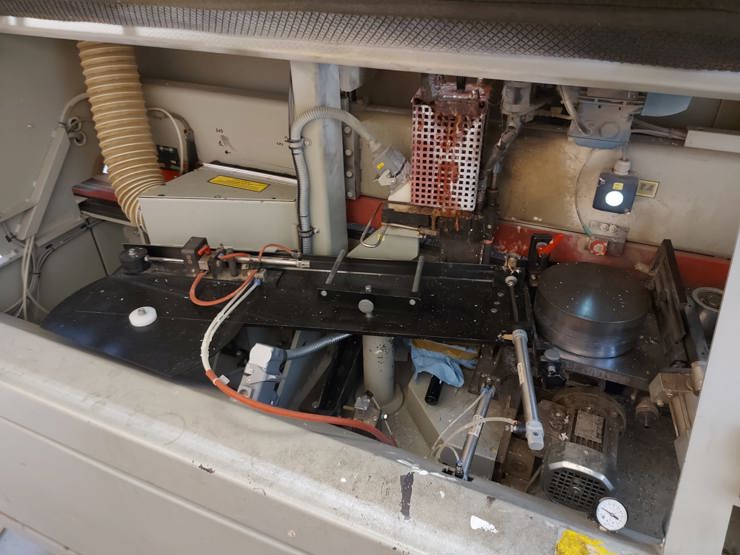

Edge banding machine OTT Tornado

M002541/M002541%20Tornado%20Alg.jpg?width=928&height=440&bgcolor=fff)

Technical Data

Melting adhesive, one-sided, working from right to left.

Application of glue by means of a glue roller

Bonding of veneer and formica strips, millamine, PVC on roll and solid edges

Edge thickness : 0.2 - 12 mm

Workpiece dimensions :

* minimum width : 70 mm

* minimum height : 8 mm

* maximum height : 52 mm

* minimum sheet length: 150 mm

Voltage : 3x 400 Volt, 50 Hz

Throughput : stepless 10-14 m/min.

Required air pressure : 6 bar

Extraction : 1 x diam. 180mm + 1 x diam 100mm

Machine dimensions :

* height : 1400 mm

* width : 900 mm

* length : 6120 mm

* weight : 3000 kg

Working height : 800 mm

Electric power : 13 kW

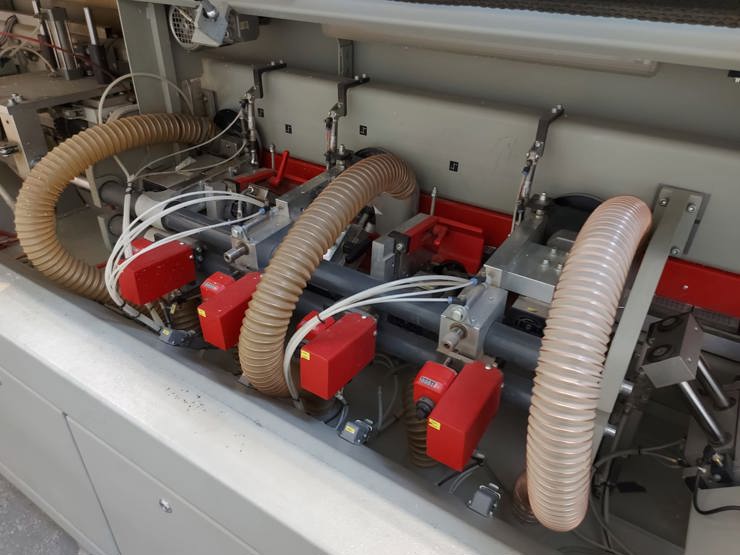

Equipped with :

Upper pressure bar with electronic positioning.

Automatic feed magazine for strips or solid slats.

Automatic magazine for roll edging (outside diameter roll up to 800 mm) with pneumatic capping for edges up to 3mm.

No manual adjustment to the edge thickness required due to adjustable and automatic feed control i.e. the different cutting and milling groups remain in place and regulation is done by feeding the sheet deeper or shallower.

COMBI-MELT gluing system for EVA and PUR glues. Controlled and adjustable via the touchscreen.

With automatic cleaning programmes.

1.5-litre glue container with separate filling nozzle as standard.

Glue system for PU cartridges 62 mm

Operation via a 7" touch screen with 480x239pixels and 256 colours.

100 Programmes stored under names and numbers.

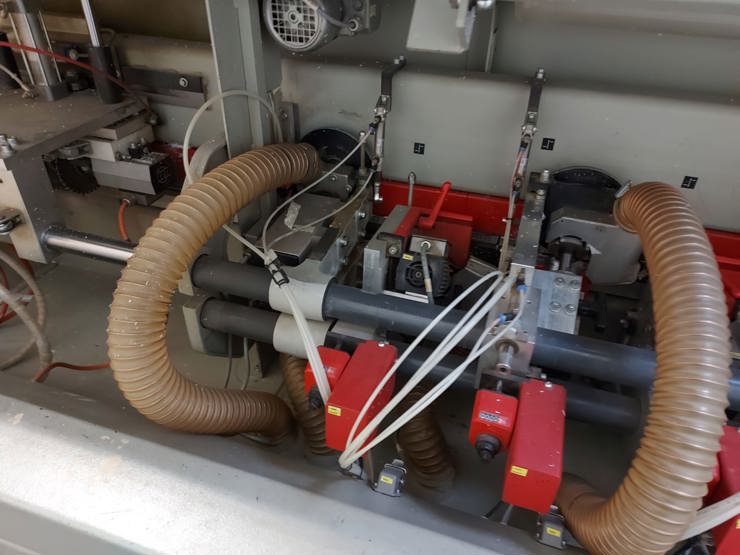

Pre-milling unit :

2 HF motors 1.5, operating in travel and counter travel, automatically controlled.

Cutting to sheet length front and rear :

2 HF motors, with adjustable positions from on PLC : 0° and 3°

Flat milling top and bottom :

2 motors

Slant milling top and bottom :

2 HF motors - two-sided scanning.+ automatic positioning.

Chamfer milling in 4 positions : 0°, 15°, 30° and 45°

Radius milling top and bottom :

2 HF motors - scanned on both sides.+ automatic positioning.

Cutters with radius 2

Scraper unit :

Two-sided scanned set for 1 radius from 2 to 5mm.

Postform milling :

2 HF motors - two-sided scanned.

Automatic horizontal positioning via touch screen programme control

Each milling motor, mills both front postform rounding, and rear postform rounding.

Flat scraper unit

Anti-static spray unit for on glue joint.

Cleaning set consisting of

2 spray heads : upper + lower : anti-PU spray

2 nozzles : upper + lower : cleaner spray

All spray heads are controlled from the PLC.

2 Cleaning brushes with automatic positioning.

Equipment for plate return system (without plate return itself)

Glueing system for PU cartridges 62mm

Similar used machnies

/formaat%202e%20hands%20website%20(20).png?width=376)

Edge banding machine OTT Pacific V12-F

M000955

/M002291%20%2001%20voor%20ap.jpg?width=376)

Edge banding machine Format 4 Tempora 60.12 E-Motion

M002291

/formaat%202e%20hands%20website%20(22).png?width=376)

Edge banding machine Hebrock AKV 3005 DK-F

M002878

Similar new machnes

/Ott%20Storm+zonder%20achtergrond.png?width=376)

Storm+

Fast, versatile edgebander

- Feed speed 12 to 20 m/min

- Workpiece height 8 -60 mm

- 3 trimming units : rough - radius - rounding

- Automatic 2 Positon scraper

/OTT%20Pacific%20+%20zonder%20achtergrond.png?width=376)

Pacific+

Edge bander compact and flexible

- Feed speed 12 to 18 m/min

- Workpiece height 8 -60 mm

- Edge thickness 0,3 - 15 mm

- 2 trimming units : rough and radius+rounding

/Ott%20TopEdge%20zonder%20achtergrond.png?width=376)

TopEdge

Heavy Duty edgebander

- Edge thickness 0,3 - 20 mm

- 4 trimming units : rough - bevel - radius - rounding

- Automatic 4-position scraper unit

- Possibility for workpiece height up to 80 mm

/M002541%20Tornado%20Alg.jpg?width=740)